product

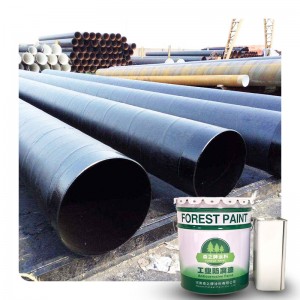

High Quality Thick Paste Epoxy Coal Tar Pitch Anticorrosive Paint

MORE DETAILS

- Vedio

- Product Features

- Product Application

- Technical Datas

- Surface treatment

- Construction Method

- Construction Points

- Storage and Transport

- Package

*Vedio:

*Product Features:

★ Excellent impact resistance, oil resistance and chemical resistance;

★ Good wear resistance, dry and wet resistance, excellent drying performance and good anti-rust performance;

★ It has low water absorption, good water resistance, strong resistance to microbial erosion and high resistance to penetration;

★ Excellent physical and mechanical properties, electrical insulation properties, wear resistance, stray current resistance, heat resistance and temperature resistance.

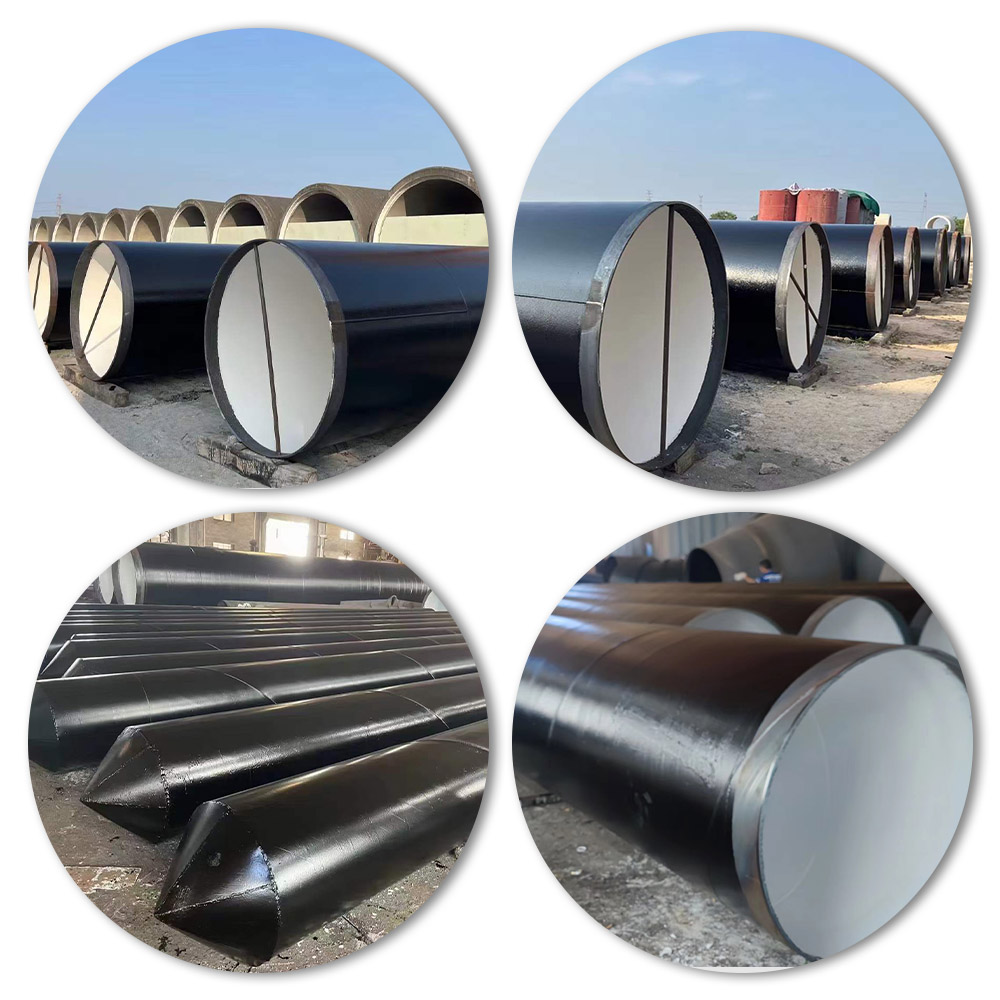

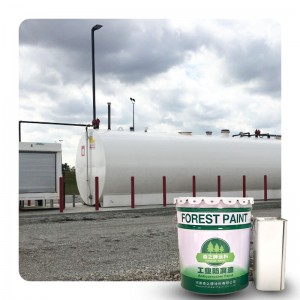

*Product Application:

It is suitable for internal and external anticorrosion of pipes, such as steel pipes, cast iron pipes and concrete pipes, which are permanently or partially buried in the ground or immersed in water. It is also suitable for buried pipelines of chemical plant buildings, highway bridges, railways, sewage treatment tanks and oil refineries. And steel storage tanks; buried cement structure, gas cabinet inner wall, bottom plate, automobile chassis, cement products, coal mine support, mine underground facilities and marine terminal facilities, wood products, underwater structures, dock steel bars, ships, sluices, Heat pipes, water supply pipes, gas supply pipes, cooling water, oil pipes, etc.

*Technical Datas:

|

Items |

Datas |

|

|

Color and appearance of paint film |

Black brown, paint film flat |

|

|

Non-volatile content,% |

≥50 |

|

|

Flashing,℃ |

29 |

|

|

Dry film thickness,um |

50-80 |

|

|

Fitness,um |

≤ 90 |

|

|

Dry time , 25℃ |

Surface dry |

≤ 4 hrs |

|

Hard dry |

≤ 24 hrs |

|

|

Density,g/ML |

1.35 |

|

|

Adhesion (marking method), grade |

≤2 |

|

|

bending strength,mm |

≤10 |

|

|

abrasive resistance (mg,1000g/200r) |

≤50 |

|

|

flexibility,mm |

≤3 |

|

|

Water resistant,30 days |

No blistering, no shedding, no discoloration. |

|

Theoretical coating consumption ( do not consider the difference of coating environment, coating method, coating technique, surface condition, structure, shape, surface area, etc.)

Light grade: primer 0.23kg/m2, top coat 0.36kg/m2;

Ordinary grade: primer 0.24kg/m2, topcoat 0.5kg/m2;

Medium grade: primer 0.25kg/m2, topcoat 0.75kg/m2;

Strengthening grade: primer 0.26kg/m2, topcoat 0.88kg/m2;

Special reinforcement grade: primer 0.17kg/m2, top coat 1.11kg/m2.

*Surface treatment:

All surfaces to be coated should be clean, dry and free of contamination.

- Oxidized steel is sandblasted to Sa2.5 grade, or pickled, neutralized, and passivated;

- Non-oxidized steel is sandblasted to Sa2.5, or sanded to St3 with pneumatic or electro-elastic grinding wheels;

- Other surfaces This product is used in other substrates, please consult our technical department.

*Construction Method:

Spray: airless or air spray. High pressure airless spraying is recommended.

Brush/Roll: The specified dry film thickness must be achieved.

*Construction Points:

1, the weld surface of the steel must be surface free of edges, smooth, no welding, no burr;

2, when thick coating construction, it is better to not drool, generally do not need to add thinner when preparing, but if the ambient temperature is too low, the viscosity is larger, you can add 1% ~ 5% of the diluent, while increasing the curing agent;

3, during construction, pay attention to changes in weather and temperature, rain, fog, snow or relative humidity greater than 80%, not suitable for construction;

4, the thickness of the glass cloth is preferably 0.1mm or 0.12mm, the latitude and longitude density is 12 × 10 / cm2 or 12 × 12 / cm2 size of defatted alkali-free or medium-alkali glass cloth, the damp glass cloth should be baked Can only be used after drying;

5, the method of filling: the joint of the anti-corrosion layer and the anti-corrosion layer of the pipe body is not less than 100mm, and the surface treatment of the lap joint needs to reach St3, wiping and no dirt;

6, fill the wound method: first remove the damaged anti-corrosion layer, if the base is not exposed, then only need to fill the coating, the glass cloth mesh topcoat has been filled;

7, visual inspection: the painted pipe must be inspected one by one, and the anti-corrosion coating is smooth, no wrinkles and air. Pinhole inspection: It can be detected by electric spark leak detector. The medium grade is 2000V, the reinforcement grade is 3000V, the special reinforcement grade is 5000V, and the average spark does not exceed 1 at every 45m2, which is qualified. If it is not qualified, the pinhole must be recoated.

*Storage and Transport:

This product is flammable. It is strictly prohibited to be fired or brought into the fire during construction. Wear protective equipment. The construction environment should be well ventilated. Avoid inhalation of solvent vapor or paint mist during construction and avoid skin contact. If the paint is accidentally splashed on the skin, immediately rinse it with a suitable cleaning agent, soap, water, etc. Wash your eyes thoroughly with water and seek medical attention immediately.