product

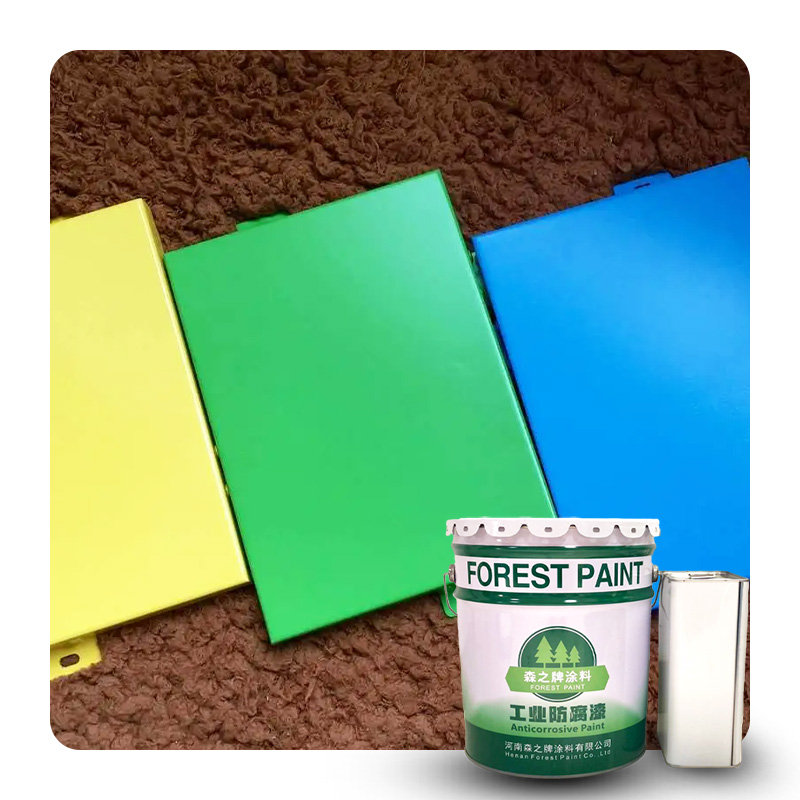

High Quality Fluorocarbon Metal Matte Finish Coating for Steel Structure

MORE DETAILS

- Product Features

- Technical Datas

- Product Application

- Double coating interval time

- Surface Treatment

- Construction method

- Construction Condition

- Package

*Product Features:

1. The coating film has strong ultraviolet resistance, excellent adhesion, flexibility, and strong impact resistance;

2. Excellent decoration and durability, adjustable color of paint film, including solid color paint and metallic paint, color retention and gloss retention, long-term discoloration;

3. Outstanding anti-corrosion performance can withstand most strong corrosive solvents, acid, alkali, water, salt and other chemicals. It does not fall off, does not change color, and has very good protection.

4. Super weather resistance, anti-corrosion and excellent self-cleaning, surface dirt is easy to clean, beautiful paint film, anti-corrosion period can be as long as 20 years, is the first choice for steel structure, bridge, building protection coating.

*Technical Datas:

|

Item |

Datas |

|

Color and appearance of paint film |

Colors and smooth film |

|

Fitness,μm |

≤25 |

|

Viscosity (Stormer viscometer), KU |

40-70 |

|

Solid content,% |

≥50 |

|

Dry time,h, (25℃) |

≤2h,≤48h |

|

Adhesion (zoned method), class |

≤1 |

|

Impact strength, kg, cm |

≥40 |

|

Flexibility,mm |

≤1 |

|

Alkali resistance,168h |

No foaming, no falling off, no discoloration |

|

Acid resistance,168h |

No foaming, no falling off, no discoloration |

|

Water resistance,1688h |

No foaming, no falling off, no discoloration |

|

Gasoline resistance,120# |

No foaming, no falling off, no discoloration |

|

Weather resistance, artificial accelerated aging 2500h |

Loss of light ≤2, chalking ≤1, loss of light ≤2 |

|

Salt spray resistant,1000h |

No foam, no falling off, no rust |

|

Humidity and heat resistance,1000h |

No foam, no falling off, no rust |

|

Solvent wiping resistance, times |

≥100 |

HG/T3792-2005

*Product Application:

It is used for anticorrosion of chemical equipment, pipelines and steel structure surfaces in harsh industrial corrosive environments. It can be painted on steel structures, bridge projects, marine facilities, drilling platforms, ports and docks, steel structures, municipal engineering, high-speed guardrails, concrete anticorrosion, etc.

*Double coating interval time:

Temperature: 5℃ 25℃ 40℃

Shortest time: 2h 1h 0.5h

Longest time: 7days

*Surface Treatment:

The quality of steel blasting and rust removal should reach Sa2.5 level or grinding wheel rust removal to St3 level: steel coated with workshop primer should be derusted and degreased twice to make.

The surface of the object should be firm and clean, free of dust and other dirt, and free of acid, alkali or moisture condensation.

*Construction method:

Spraying: Airless spraying or air spraying. High-pressure airless spraying is recommended.

Brushing / Rolling: The specified dry film thickness must be achieved.

*Construction Condition:

1, Base temperature is not less than 5℃, the relative humidity of 85% (temperature and relative humidity should be measured near the base material), fog, rain, snow, wind and rain is strictly prohibited construction.

2, Before painting the paint, clean the coated road surface to avoid impurities and oil.

3, The product can be sprayed, brushed or rolled. It is recommended to spray with special equipment. The amount of thinner is about 20%, the application viscosity is 80S, the construction pressure is 10MPa, the nozzle diameter is 0.75, the wet film thickness is 200um, and the dry film thickness is 120um. The theoretical coating rate is 2.2 m2/kg.

4, If the paint is too thick during construction, be sure to dilute it to the required consistency with a special thinner. Do not use thinner.