product

High Elastic Anti-Cracking Property Acrylic Waterproof Flexible Coating

MORE DETAILS

- Vedio

- Product Features

- Product Application

- Construction Requirements

- Product Parameters

- Transport and Storage

- Package

*Product Features:

1. It can be applied on wet and complex base surfaces, and the coating film has no joints and strong integrity;

2. Strong adhesion, high tensile strength, good elongation, and strong ability to adapt to the cracking and deformation of the base layer;

3. Liquid construction, room temperature curing, easy operation and short construction period;

*Product Application:

1. Waterproof treatment of roofs, walls, toilets, window sills, etc. of old and new buildings.

2. Waterproof and moisture-proof treatment of various parts of underground buildings.

3. It can be used on dry or wet concrete surface, metal, wood, gypsum board, SBS, APP, polyurethane surface, etc.

4. Sealing of expansion joints, grid joints, downspouts, wall pipes, etc.

*Construction Requirements:

1. Base surface treatment: The construction surface should be solid, flat, free of dust, oil, and clear water.

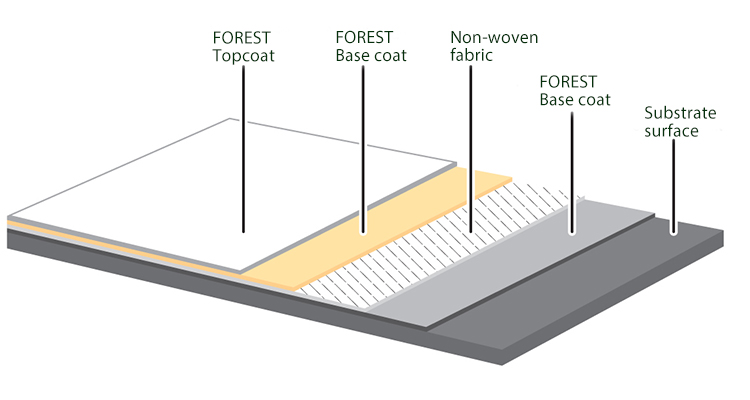

2. Use a rubber scraper or roller brush for coating, generally two to three times. If the coating is too thick, add an appropriate amount of water and mix it well.

3. For special parts, non-woven fabric or glass fiber cloth can be added between the middle layer and the upper layer to improve the coating strength.

*Product Parameters:

|

No. |

Items |

Technical index |

0ur data |

|

|

1 |

Solid content, % |

≥ 65 |

72 |

|

|

2 |

Tensile Strength, MPa≥ |

1.5 |

1.8 |

|

|

3 |

Fracture extension, %≥ |

300 |

320 |

|

|

4 |

Low temperature bendability, Φ10mm, 180° |

-20℃ No cracks |

-20℃ No cracks |

|

|

5 |

Impermeability,0.3Mpa,30min |

Impermeable |

Impermeable |

|

|

6 |

Dry time, h |

Touch dry time≤ |

4 |

2 |

|

Full dry time≤ |

8 |

6.5 |

||

|

7 |

Tensile Strength |

Retention rate after heat treatment,% |

≥80 |

88 |

|

Retention rate after alkali treatment,% |

≥60 |

64 |

||

|

Retention rate after acid treatment,% |

≥60 |

445 |

||

|

Divergent climate aging treatment,% |

≥80-150 |

110 |

||

|

Retention rate after UV treatment,% |

≥70 |

70 |

||

|

8 |

Elongation at break |

Divergent climate aging treatment,% |

≥200 |

235 |

|

Heat treatment,% |

≥65 |

71 |

||

|

Alkali treatment,% |

≥200 |

228 |

||

|

Acid treatment,% |

200 |

217 |

||

|

UV treatment,% |

≥65 |

70 |

||

|

9 |

Heating expansion ratio |

Elongation,% |

≤1.0 |

0.6 |

|

Shorten,% |

≤1.0 |

0.8 |

||

*Transport and Storage:

1. Do not construct under 0°C or in the rain, and do not construct in a particularly humid and non-ventilated environment, otherwise it will affect the film formation;

2. After construction, all parts of the entire project, especially weak links, should be carefully checked to find out problems, find out the reasons and repair them in time.

3. It should be sealed and stored in a cool and ventilated warehouse with a shelf life of one year.