product

Anti scratch high hardness epoxy floor paint for industrial car parking flooring

MORE DETAILS

- Vedio

- Product Features

- Product Application

- Technical Datas

- Surface treatment

- Recoating interval time

- Construction Steps

- Construction Caution

- Use and Maintenance

- Storage And Shelf Life

- Package

*Product Features:

1, Two component paint

2, The film is complete seamless and tenacity

3, Easy to clean, do not gather dust and bacteria

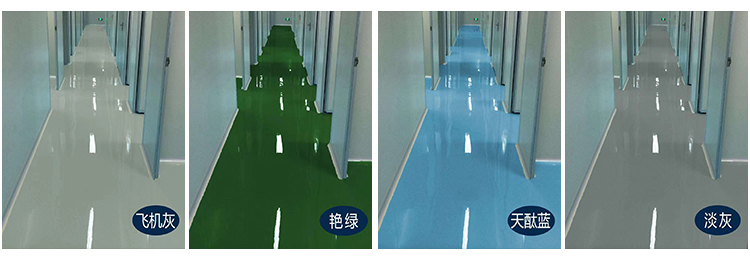

4, Smooth surface, more color, water resistance

5, Non-toxic, meets the sanitary requirements;

6, Oil resistance, chemical resistance

7, Anti slip performance, good adhesion, impact resistance, wear resistance

*Product Application:

Widely used in electronics factories, machinery manufacturers, hardware factories, pharmaceutical factories, automobile factories, hospitals, aviation, aerospace bases, laboratories, offices, supermarkets, paper mills, chemical plants, plastic processing plants, textile mills, tobacco factories, Surface coating of confectionery factories, wineries, beverage factories, meat processing plants, parking lots, etc.

*Technical Datas:

|

Item |

Datas |

|

|

Color and appearance of paint film |

Transparent and smooth film |

|

|

Dry Time, 25 ℃ |

Surface Dry, h |

≤4 |

|

Hard Dry, h |

≤24 |

|

|

Hardness |

H |

|

|

Acid Resistant(48 h) |

Complete film, non blister, none fall off, allows slight loss of light |

|

|

Adhesion |

≤1 |

|

|

Wear resistance,(750g/500r)/g |

≤0.060 |

|

|

Impact resistance |

I |

|

|

Slip resistance (dry friction coefficient) |

≥0.50 |

|

|

Water Resistant(168h) |

non blister, none fall off, allows slight loss of light, Recover in 2 hrs |

|

|

120# Gasoline, 72h |

non blister, none fall off, allows slight loss of light |

|

|

20% NaOH, 72h |

non blister, none fall off, allows slight loss of light |

|

|

10% H2SO4, 48h |

non blister, none fall off, allows slight loss of light |

|

Standard reference:HG/T 3829-2006;GB/T 22374-2008

*Surface treatment:

Completely remove the oil pollution on the surface of cement, sand and dust, moisture and so on, to ensure that the surface is smooth, clean, solid, dry, non foaming, not sand, no cracking, no oil. Water content should not be greater than 6%, the pH value is not greater than 10. The strength grade of cement concrete is not less than C20.

*Recoating interval time:

|

Ambient temperature (℃) |

5 |

25 |

40 |

|

Shortest Time(h) |

32 |

18 |

6 |

|

Longest Time(day) |

14 |

7 |

5 |

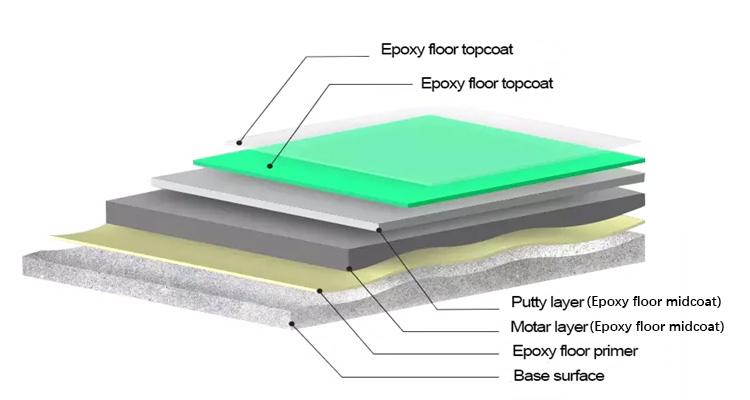

*Construction Steps:

1, Base Floor Treatment

Use a grinder or a batch of knives to remove particles and debris from the ground, then clean it with a broom, and then grind it with a grinder. Make the floor surface clean, rough, and then clean. Use a vacuum cleaner to remove dust to increase the primer. Adhesion to the ground (groundholes, cracks need to be filled with putty or medium mortar after the primer layer).

2, Scraping the Epoxy Seal Primer

The epoxy primer is mixed in proportion, stirred evenly, and evenly coated with a file to form a full resin surface layer on the ground, thereby achieving the effect of high permeability and high adhesion of the medium coating.

3, Scraping the Midcoat With Mortar

The epoxy intermediate coating is mixed in proportion, and then an appropriate amount of quartz sand is added, and the mixture is uniformly stirred by a mixer, and then uniformly coated on the floor with a trowel, so that the mortar layer is tightly bonded to the ground (quartz sand is 60-80 mesh, It can effectively fill the ground pinholes and bumps), so as to achieve the effect of leveling the ground. The greater the amount of medium coating, the better the leveling effect. The amount and process can be increased or decreased according to the designed thickness.

4, Scraping the Midcoat with Putty

After the coating in the mortar is completely cured, use a sanding machine to completely and gently polish, and then use a vacuum cleaner to absorb the dust; then add the appropriate medium coating to the appropriate amount of quartz powder and stir evenly, and then evenly apply with a file to make It can fill the pinholes in the mortar.

5, Coating the Topcoat

After the surface-coated putty is completely cured, the epoxy flat-coating topcoat can be evenly coated with a roller, so that the entire ground can be environmentally friendly, beautiful, dustproof, non-toxic and volatile, and high-quality and durable.

*Construction Caution:

1. The ambient temperature at the construction site should be between 5 and 35 ° C, the low temperature curing agent should be above -10 ° C, and the relative humidity should be greater than 80%.

2. The constructor should make actual records of construction site, time, temperature, relative humidity, floor surface treatment, materials, etc., for reference.

3. After the paint is applied, the relevant equipment and tools should be cleaned immediately.

*Use and Maintenance:

1. When the paint is finished, do not use it during the maintenance period, and strengthen ventilation and fire prevention measures.

2. The use of the floor surface, the production personnel are not allowed to wear leather shoes with iron nails to walk on it.

3. All work tools must be placed on a fixed frame. It is strictly forbidden to hit the ground with metal parts with sharp angles, causing damage to the floor paint floor.

4. When installing heavy equipment such as equipment in the workshop, the supporting points that contact the ground should be covered with soft rubber and other soft materials. It is strictly forbidden to use metal such as iron pipes to connect the equipment on the ground.

5. When high-temperature operation such as electric welding is carried out in the workshop, refractory materials such as asbestos cloth should be used in the place where the electric spark is splashed to prevent burnt paint.

6. Once the floor is damaged, use the paint to repair it in time to prevent the oil from penetrating into the cement through the damage, causing the large-area paint to fall off.

7. When cleaning large areas in the workshop, do not use strong chemical solvents (xylene, banana oil, etc.), generally use detergent, soap, water, etc., with a washing machine.

*Storage And Shelf Life:

1, Store at the tempestuous of 25°C or cool and dry place. Avoid from sunlight, high temperature or high humidity environment.

2, Use up as soon as possible when opened. It is strictly forbidden to expose to the air for a long time after it is opened to avoid affecting the quality of the products. The shelf life is six months in the room temperature of 25°C.