product

Waterproofing Alkali Resistant Chlorinated Rubber Paint

MORE DETAILS

- Vedio

- Product Features

- Technical Datas

- Product Application

- Construction Method

- Surface Treatment

- Transport and Storage

- Package

*Product Features:

1. Good adhesion to steel, concrete and wood.

2, drying fast, construction is not subject to seasonal restrictions. It can be applied normally from -20 to 40 degree , and can be recoated at intervals of 4 to 6 hours.

3, easy to use. Single component, stir well after opening the barrel. It can be applied by various methods such as high pressure airless spraying, brush coating and roller coating.

4, resistant to sunlight aging, to protect the middle and bottom coating.

5, good corrosion resistance. Chlorinated rubber is an inert resin. Water vapor and oxygen have very low permeability to paint film. It has excellent water resistance, salt, alkali and resistance to various corrosive gases. It has anti-mildew, flame retardant properties, weather resistance and Durable.

6, easy to maintain. The adhesion between the old and new paint layers is good, and it is not necessary to remove the strong old paint film during the overcoating.

*Technical Datas:

|

After stirring in the state in the container, |

No hard blocks are uniform |

|

Fitness,um |

≤40 |

|

Viscosity,KU |

70-100 |

|

Thickness of Dry film, um |

70 |

|

Impact strengtht, kg, cm |

≥50 |

|

Surface Dry time(h) |

≤2 |

|

Hard Dry time (h) |

≤24 |

|

Covering, g/㎡ |

≤185 |

|

Solid content % |

≥45 |

|

Bending resistant, mm |

10 |

|

Acid resistance |

48h no change |

|

Alkali resistance |

48h no change |

|

Wear resistance,mg, 750g/500r |

≤45 |

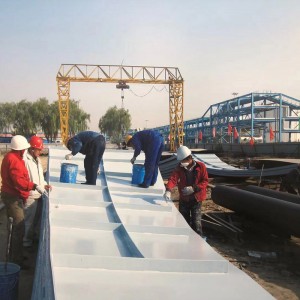

*Product Application:

It is suitable for anti-corrosion of wharf, ship, water steel structure, oil tank, gas tank, ramp, chemical equipment and steel structure of factory building. It is also suitable for concrete surface decoration protection of walls, pools and underground ramps. Not suitable for use in environments where benzene solvents are in contact.

*Construction Method:

Spray: Non-air spray or air spray. High pressure non-gas spray.

Brush/roller: recommended for small areas, but must be specified.

Stir well after opening the barrel, and adjust the viscosity with chlorinated rubber thinner and apply directly.

Steel surface clear oil coating, it is best to use sandblasting rust to a minimum of Sa / 2 of GB / T 8923, preferably to reach Sa 2 1/2. When the construction conditions are limited, tools can also be used to derust to St 3 level. After the steel surface treatment is qualified, it must be painted as soon as possible before the rust is removed, and 2 to 3 chlorinated rubber coatings are applied. The concrete should be dry, remove the loose material on the surface, present a flat and solid surface, and apply 2 to 3 chlorinated rubber coatings.

*Surface Treatment:

All surfaces to be coated should be clean, dry and free of contamination. All surfaces shall be in accordance with ISO 8504:2000 before painting.

*Transport and Storage:

1, this product should be sealed and stored in a cool, dry, ventilated place, away from fire, waterproof, leak-proof, high temperature, sun exposure.

2, Under the above conditions, the storage period is 12 months from the date of production, and can continue to be used after passing the test, without affecting its effect.