product

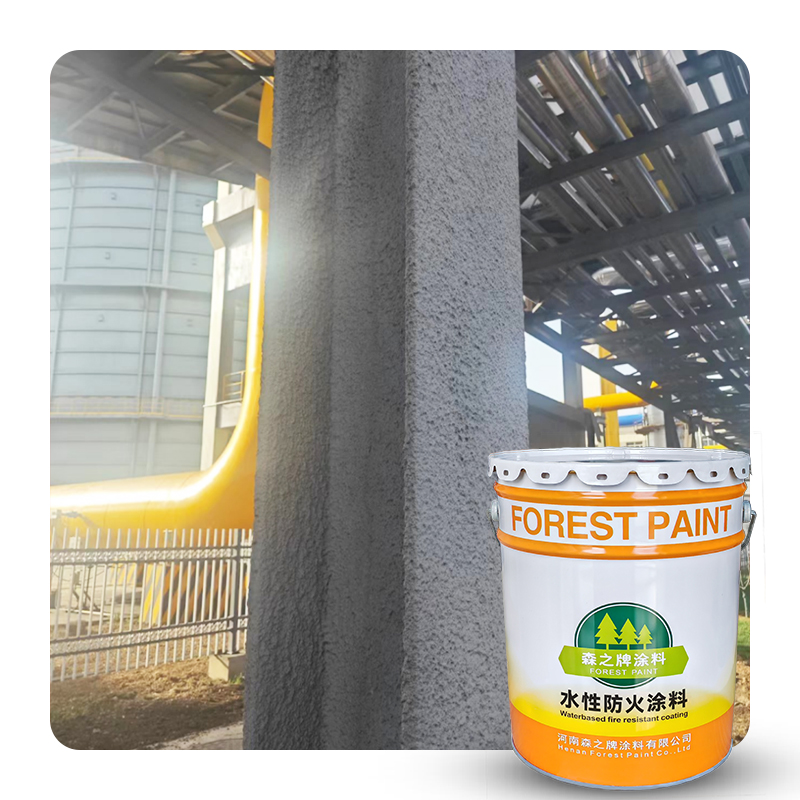

Waterbased Intumescent Fire Resistant Paint

MORE DETAILS

- Vedio

- Product Formation

- Product Feature

- Product Application

- Technical Data

- Product Construction

- Surface Treatment

- Construction Condition

- Auxiliary Paint

- Product Package

*Product Formation:

The paint is sprayed on the surface of the steel structure, usually plays a decorative role. In the event of fire, it expands and thickens and carbonizes to form a non-flammable sponge-like carbon layer, thereby improving the fire resistance limit of the steel structure to more than 2.5 hours, winning the fire extinguishing time and effectively protecting. Steel structures are protected from fire.

*Product Feature:

1, silicone-acrylic emulsion and chlorine partial emulsion mixed, can improve the water resistance and fire resistance of indoor thin steel structure fire retardant coating, but to do a good compatibility test to prevent the occurrence of demulsification.

2, the addition of inorganic potassium silicate can enhance the compactness of the coating film, thereby improving the water resistance and fire resistance of the coating film, but must be pre-mixed with the base material when added, and then slowly added to the pre-slurry to prevent polyphosphoric acid The board is formed into coarse particles.

3, Hydroxypropyl methylcellulose and bentonite can effectively provide the required water retention and thixotropic value of the system, enhance the initial dry crack resistance, and easy to spray, scrape coating construction.

*Product Application:

Use on the steel structure of the building within 2.5 hours of the fire resistance limit, such as beams, slabs, roof load-bearing members in a type of building; columns, beams, slabs and various light steel beams and grids in the second type of buildings.

*Technical Data:

|

No. |

Items |

Qualification |

|||

|

1 |

the state in the container |

No caking, uniform state after stirring |

|||

|

2 |

Appearance and color |

No significant difference in appearance and color barrel samples after drying of the coating |

|||

|

3 |

Dry Time |

Surface Dry,h |

≤12 |

||

|

4 |

Initial drying and crack resistance |

Allow 1-3 cracks with a width of less than 0.5 mm. |

|||

|

5 |

Bond strength, mpa |

≥0.15 |

|||

|

6 |

Water resistance, h |

≥ 24 h, the coating has no layer, no foaming and no shedding. |

|||

|

7 |

Cold and heat resistant cycle |

15 times, the coating shall be free from cracking, no spalling, no blistering |

|||

|

8 |

Fire Resistant |

Dry film thickness, mm |

≥1.6 |

||

|

Fire resistance limit (i36b/i40b), h) |

≥2.5 |

||||

|

9 |

Coverage |

Fireproof time |

1h |

2h |

2.5h |

|

Coverage,kg/sqm |

1.5-2 |

3.5-4 |

4.5-5 |

||

|

Thickness,mm |

2 |

4 |

5 |

||

*Product Construction:

Construction environment:

Before the construction process and coating drying and curing, the ambient temperature should be maintained at 5-40 ° C, relative humidity > 90%, the site ventilation should be good.

It can be applied by spraying, brushing, roller coating, etc. After the coating applied in the previous application is basically dried and solidified, it is sprayed once again, usually at intervals of 8-24 hours, until the desired thickness.

1. The construction of the fireproof coating, because the fireproof coating is generally rough, it is recommended to use a self-weighting spray gun with automatic pressure regulation of 0.4-0.6Mpa; for partial repair and small area construction, it can be brushed, sprayed or rolled, using one or Many methods are convenient to construct. The spray nozzle for spray primer can also be used for spray coating when the adjustable diameter is 1-3mm. If painted manually, the number of brushing passes should be increased.

2. The thickness of each pass shall not exceed 0.5mm when spraying, and it shall be sprayed once every 8 hours in fine weather. When spraying one coat of paint, it must be dried before the spray is applied. The thickness of each line of manual spraying is thin, and the number of tracks is measured according to the thickness.

3. According to the refractory time requirements of the coated steel structure, the corresponding coating thickness is determined. The theoretical coating consumption per 1 square meter per 1 square meter of coating is 1-1.5kg.

4. After spraying the fire retardant coating, it is recommended to apply 1-2 times of acrylic or polyurethane anticorrosive topcoat to ensure that the paint film is smooth and smooth and has a good decorative effect.

*Surface Treatment:

All surfaces must be clean, dry and free of contamination. Before painting, should be assessed and treated in accordance with standard of the ISO8504:2000.

*Construction Condition:

Base temperature is not less than 0℃, and at least above the air dew point temperature 3℃, the relative humidity of 85% (temperature and relative humidity should be measured near the base material), fog, rain, snow, wind and rain is strictly prohibited construction.

*Auxiliary Paint:

Alkyd primer or epoxy zinc rich primer, epoxy primer, and the topcoat will be alkyd topcoat, enamel, acrylic topcoat, acrylic enamel and so on.