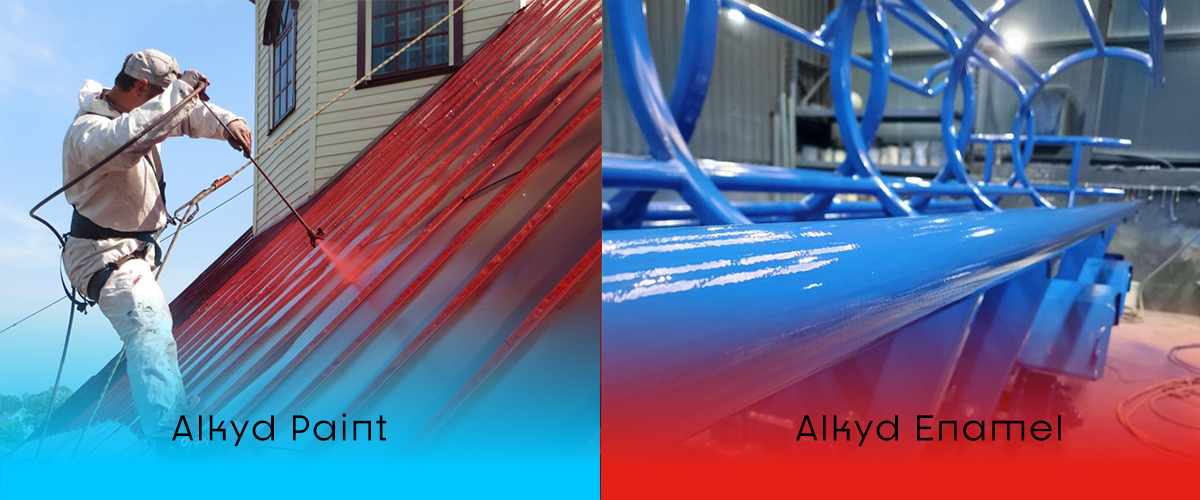

In the world of protective and decorative coatings, few products are as widely used—or as frequently confused—as alkyd paint and alkyd enamel. While both share a common chemical heritage, their formulations, performance characteristics, and ideal applications differ significantly. For professionals in manufacturing, construction, and industrial maintenance, as well as discerning DIY enthusiasts, understanding these distinctions is crucial for ensuring durability, aesthetics, and cost-effectiveness. This in-depth analysis explores the nuances between these two coating types, providing the clarity needed to make an informed decision for your next project.

1. Performance Characteristics: Drying, Durability, and Defense

Alkyd Paint Performance Profile:

Adhesion and Flexibility: Exhibits excellent adhesion to a variety of substrates (wood, primed metal, masonry) and retains good flexibility, resisting cracking and peeling.

Weather Resistance: Offers decent resistance to moisture and UV degradation but can chalk (form a powdery surface) and yellow over time, especially in direct sunlight. It is susceptible to mildew growth in persistently damp, humid environments.

Chemical and Abrasion Resistance: Provides fair resistance to mild chemicals, oils, and household cleaners. Its abrasion resistance is moderate, making it suitable for surfaces with light to moderate wear.

Alkyd Enamel Performance Profile:

Film Integrity and Gloss: Forms a harder, tougher, and more continuous film. It delivers a high-gloss, smooth finish that is easier to clean and more resistant to staining.

Enhanced Durability: Superior resistance to abrasion, scuffing, impact, and moisture infiltration. Its harder film provides better defense against corrosion for metal substrates when applied over a proper primer.

Environmental Resistance: Generally features improved UV stabilizers and resin systems for better gloss retention and color stability outdoors. It is also more resistant to mold and mildew.

The Takeaway: Alkyd enamel trades some of the traditional alkyd’s flexibility for significantly greater surface hardness, faster cure, and enhanced resistance to physical and environmental wear.

2. Application Domains: Matching the Coating to the Challenge

Ideal Uses for Alkyd Paint:

Architectural & Decorative: Interior and exterior trim, doors, windows, and walls where a balance of durability and ease of application is valued.

General Woodworking: Furniture, cabinets (especially for a vintage “brush-mark” finish), and decorative wood items.

General Maintenance: For fences, outdoor furniture, and primed metal surfaces in non-severe environments.

Primers: Alkyd-based primers remain a top choice for sealing porous surfaces like wood or water-stained ceilings due to their excellent sealant properties.

Ideal Uses for Alkyd Enamel:

Industrial Equipment: Machinery, factory tools, pumps, and mechanical parts requiring a tough, wipe-clean surface resistant to oils and solvents.

Metal Fabrication: Railings, storage tanks, agricultural implements, structural steel (in mild environments), and metal doors.

Automotive and Marine (Non-immersive): Truck beds, trailer interiors, engine blocks, and boat interiors where high abrasion and fuel/oil resistance are needed.

Appliances and Consumer Durables: Toolboxes, filing cabinets, shelving units, and appliance touch-ups.

High-Traffic Architectural Elements: Hospital trim, kitchen cabinets, bathroom fixtures, and handrails that require frequent cleaning and scrubbing.

3. Application Techniques and Long-Term Maintenance

Applying Alkyd Paint:

Surface Prep: Critical. Surfaces must be clean, dry, and free of loose material. Sanding glossy surfaces is necessary for adhesion. On new wood, a primer is essential.

Application: Applied via brush, roller, or spray. Brushing is common and allows the paint to flow into substrates. It has a longer “open time,” allowing for smoother brush-stroke leveling.

Recoat & Cure: Typically requires 24 hours between coats. Full cure and hardness can take up to 30 days. Avoid placing objects on the surface during this period.

Maintenance: May require more frequent touch-ups in high-wear or exterior applications. Cleaning should be gentle to avoid damaging the film.

Applying Alkyd Enamel:

Surface Prep: Even more critical. Surfaces often require thorough degreasing and abrasive blasting or grinding for metal to ensure maximum adhesion of the hard film.

Application: Best applied in thin, even coats to avoid runs or sags, as it sets quickly. Spray application is very common in industrial settings for a flawless finish. Good ventilation is vital due to faster solvent release.

Recoat & Cure: Follow the manufacturer’s “recoat window” precisely—often a matter of hours. Missing this window can lead to intercoat adhesion problems, requiring sanding.

Maintenance: Its durable nature means less frequent repainting. Surfaces are easily cleaned with stronger detergents without damaging the finish. Inspect for chips or scratches on metal, as these can be focal points for corrosion.

4. The Modern Context: Environmental and Regulatory Considerations

Many modern “alkyd” products are now waterborne alkyd hybrids, offering easier cleanup and lower odor while retaining much of the performance. However, for the highest durability in industrial settings, solvent-borne alkyd enamels are still prevalent.

Conclusion and Selection Framework

Choosing between alkyd paint and alkyd enamel is not about which is universally better, but about which is optimal for your specific need.

Choose Standard Alkyd Paint when:

The project is general-purpose or architectural.

You prioritize ease of application, adhesion over complex surfaces, and cost-effectiveness.

The environment is moderate, with only occasional exposure to moisture, abrasion, or chemicals.

A slower drying time is beneficial for achieving a smooth, brush-applied finish.

Choose Alkyd Enamel when:

The substrate is metal or another hard surface subject to wear, impact, or frequent cleaning.

A hard, high-gloss, and easily cleanable finish is a primary requirement.

The environment involves exposure to oils, solvents, or moderate industrial chemicals.

You need a faster turnaround due to quicker drying and curing times.

Final Recommendation: Always consult the manufacturer’s specifications. For critical applications, conduct a small test application to ensure compatibility with the substrate and to verify the finish meets your aesthetic and performance expectations. By aligning the coating’s inherent strengths with the demands of your project, you ensure longevity, protection, and a professional result.

What’s Next?

Considering a specific upcoming project, such as refinishing outdoor metal railings or repainting interior wood trim? Understanding the exact environmental exposure and desired finish lifespan can help pinpoint which alkyd-based product—or even a modern hybrid alternative—would deliver the best value and performance for your situation.

Post time: Jan-29-2026