product

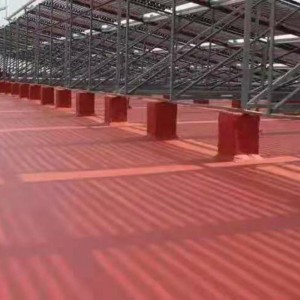

High Elastic Liquid Red Rubber Waterproof Coating

MORE DETAILS

- Vedio

- Product Features

- Product Application

- Product Parameters

- Construction Requirements

- Transport and Storage

- Package

*Vedio:

*Product Features:

1. One-component, cold construction, can be applied by brushing, rolling, scraping, etc.

2. It can be applied on wet (no clear water) or dry base surface, and the coating is tough and highly elastic.

3. It has strong adhesion to masonry, mortar, concrete, metal, foam board, insulation layer, etc.

4. The product is non-toxic, tasteless, environmentally friendly, and has good extensibility, elasticity, adhesion and film-forming properties.

5. most color can be. Red, grey, blue and so on.

*Product Application:

1. It is suitable for anti-seepage projects in non-long-term flooded environments such as roofs, walls, bathrooms, and basements;

2. It is suitable for waterproof projects such as metal roofing color steel tiles;

3. It is suitable for the sealing of expansion joints, grid joints, downspouts, wall pipes, etc.

*Product Parameters:

|

No. |

Items |

Technical index |

|

|

1 |

Tensile Strength, MPa |

≥ 2.0 |

|

|

2 |

Elongation at break,% |

≥400 |

|

|

3 |

Low temperature bendability, Φ10mm, 180° |

-20℃ No cracks |

|

|

4 |

Impermeable, 0.3Pa, 30min |

impermeable |

|

|

5 |

Solid content, % |

≥70 |

|

|

6 |

Dry Time, h |

Surface,h≤ |

4 |

|

Hard dry,h≤ |

8 |

||

|

7 |

Tensile strength retention after treatment |

Heat treatment |

≥88 |

|

Alkali treatment |

≥60 |

||

|

acid treatment |

≥44 |

||

|

artificial aging treatment |

≥110 |

||

|

8 |

Elongation at break after treatment |

Heat treatment |

≥230 |

|

Alkali treatment |

|||

|

acid treatment |

|||

|

artificial aging treatment |

|||

|

9 |

Heating expansion ratio |

elongation |

≤0.8 |

|

shorten |

≤0.8 |

||

*Construction Requirements:

1. Base surface treatment: The base surface must be flat, firm, clean, free of clear water and no leakage. Cracks in uneven places must be leveled first, leaks must be plugged first, and the yin and yang corners should be rounded;

2. Coating with rollers or brushes, according to the selected construction method, layer by layer in the order of layering → lower coating → non-woven fabric → middle coating → upper coating;

3. The coating should be as uniform as possible, without local deposition or too thick or too thin.

4. Do not construct under 4℃ or in the rain, and do not construct in a particularly humid and non-ventilated environment, otherwise it will affect the film formation;

5. After construction, all parts of the entire project, especially weak links, should be carefully checked to find out problems, find out the reasons and repair them in time.

*Transport and Storage:

Store in a cool, dry, ventilated indoor warehouse at a temperature of 5-30 C;

The storage period is 6 months. Products that exceed the storage period can be used after passing the inspection.