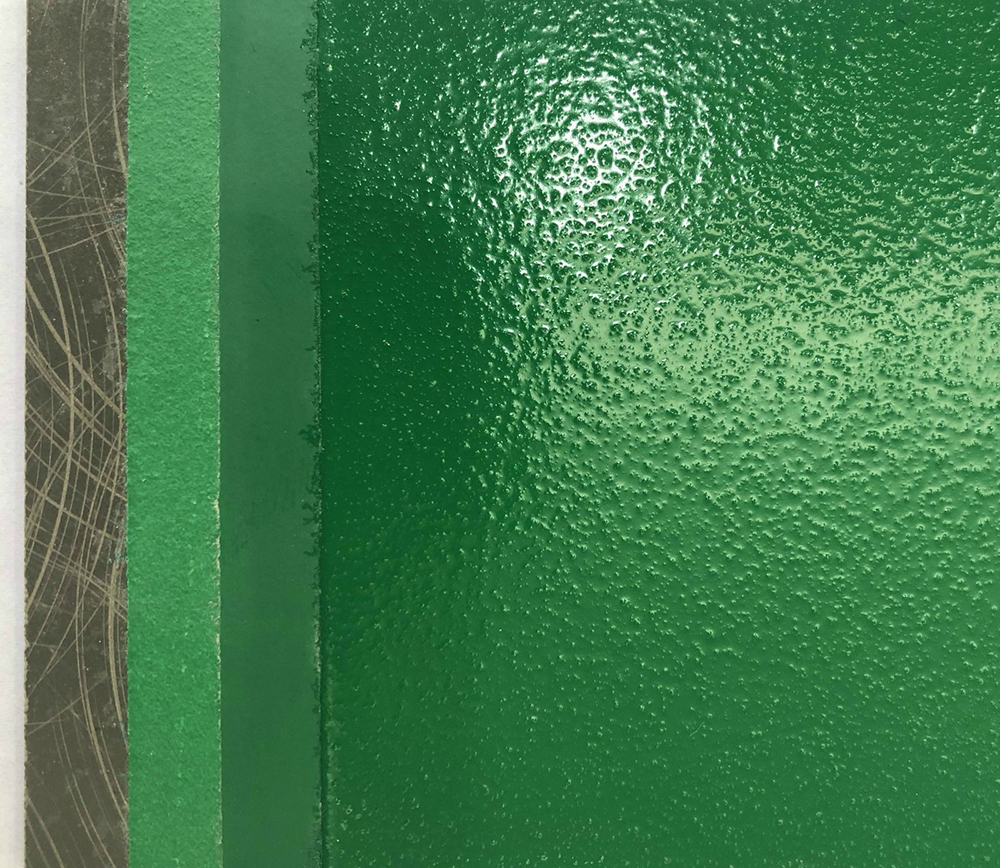

Epoxy wear-resistant micro-bead floor coating is a floor coating made of epoxy resin as the base material, with functional fillers such as wear-resistant micro-beads added, and made through a special process. It has excellent wear resistance, chemical resistance and compression resistance, and is widely used in industrial plants, warehouses, workshops, shopping malls and other places.

Feature:

1. Strong wear resistance: The micro-bead component in the epoxy wear-resistant micro-bead floor coating can effectively improve the wear resistance of the floor and is suitable for high-frequency heavy load and friction environments.

2. Anti-chemical corrosion: The coating has good resistance to a variety of chemical substances and can effectively prevent the erosion of the ground by chemicals such as oil, acid and alkali.

3. Excellent adhesion: The properties of epoxy resin make the adhesion between the coating and the substrate extremely strong, which can effectively prevent peeling and flaking.

4. Easy to clean: The smooth surface makes cleaning easier and reduces maintenance costs.

5. Aesthetics: A variety of colors and textures can be provided according to customer needs to enhance the aesthetics of the space.

Application fields

Epoxy wear-resistant micro-bead floor coating is suitable for a variety of places, including but not limited to:

- Industrial Plant: Withstands working environment with heavy machinery and equipment.

– Warehouse: A wear-resistant and pressure-resistant floor is required.

– Workshop: has high requirements for wear resistance and cleanliness of the floor.

– Shopping malls and supermarkets: require attractive and wear-resistant floors.

– Parking lot: A place that is subject to frequent entry and exit of vehicles and heavy pressure.

Construction technology

1. Surface preparation: Make sure the ground is dry and clean, and remove oil, dust and loose materials.

2. Primer construction: Apply epoxy primer to enhance adhesion to the base surface.

3. Mid-coat construction: Add wear-resistant microbeads to form a wear-resistant layer to improve the wear resistance of the floor.

4. Topcoat application: Apply epoxy topcoat to form a smooth surface, increase aesthetics and chemical resistance.

5. Curing: After the coating is completely cured, it can be used later.

Precautions

(1) During construction, attention should be paid to the ambient temperature and humidity to ensure the curing effect of the coating.

(2) During the construction process, appropriate protective equipment must be worn to ensure safety.

(3) After completion, it is recommended to avoid placing heavy objects on the surface for a period of time to ensure that the coating is fully cured.

Post time: Mar-07-2025